Change starts from within – Inflight Magazine, Sustainability Feature

With the journey to net zero 2050 in full swing, aircraft cabin design will play a key role in the shift to more sustainable practices for airlines and operators. Elena Lodge reports.

On hearing the phrase “sustainable aviation”, you might first think of new technologies, zero-emissions flight or sustainable aviation fuel (SAF). All of these are vital to meeting the ambitious net zero 2050 target, but not to be forgotten is the aircraft cabin interior.

Not only is the aircraft cabin a key passenger touchpoint, it also provides ample opportunity for cutting emissions and reducing the environmental impact of a flight with just a few eco-conscious tweaks. For instance, selecting the lightest weight products possible can help to reduce emissions, while considering the material and lifecycle of a product can help maximise the lifecycle of a product and minimise waste.

As operators and OEMs alike seek to optimise their operations and reduce carbon emissions wherever possible, the cabin interior is one area of operations at the forefront of this shift to sustainable aviation. As the famous maxim goes, “change starts from within”, so what are these changes and how are they helping to bridge the gap to net zero?

“Smarter interior designs and the use of low-carbon or more sustainable luxury materials could help to limit the environmental impact of refits.”

Monica Sogn, Head of CMF, Tangerine

BY DESIGN

London-based strategic design consultancy Tangerine specialises in transportation design, with a number of clients within the aviation and aerospace industry.

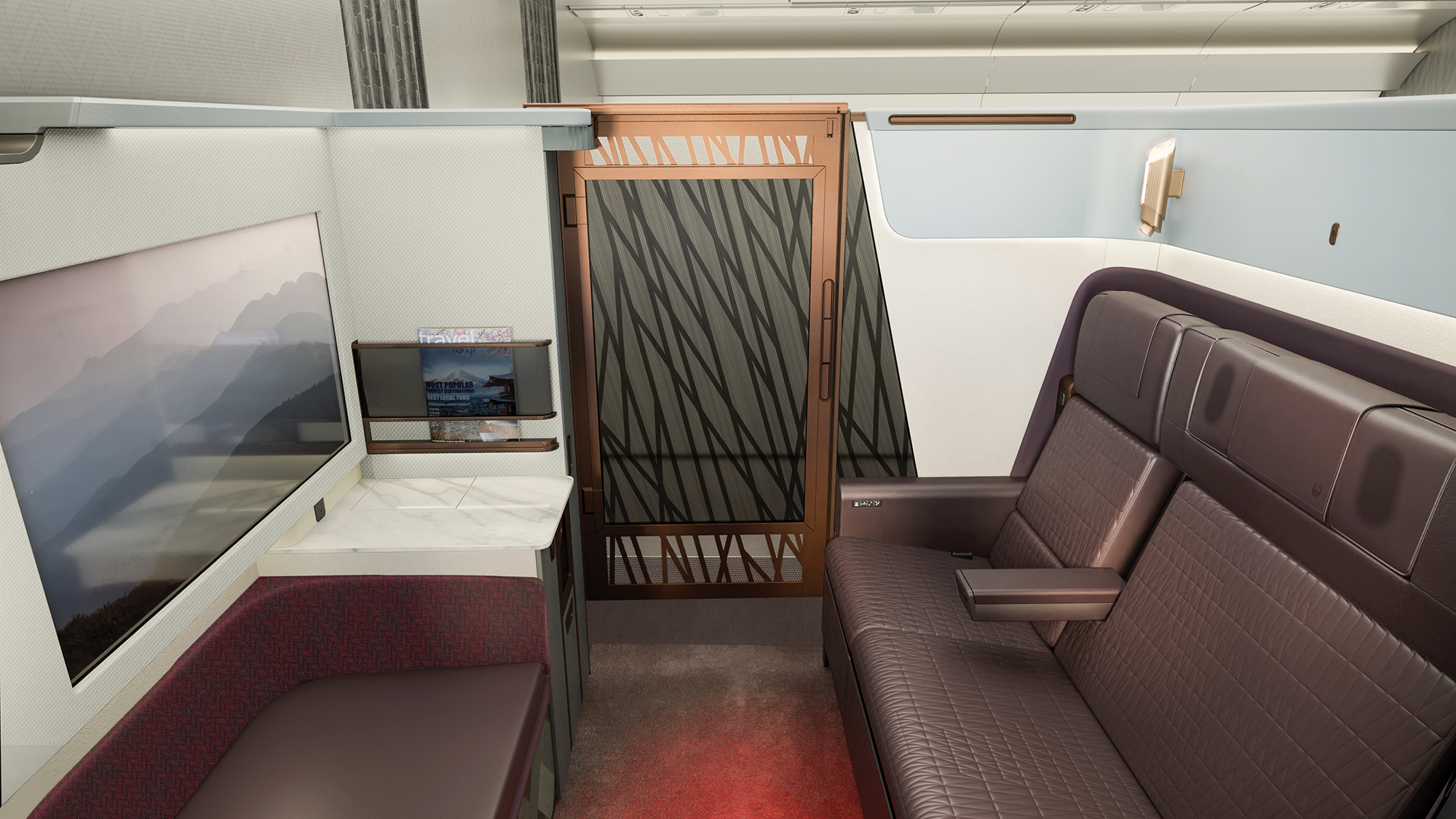

The last six months has seen Tangerine launch or unveil projects with LOT Polish Airlines’ B787, Southwest Airlines’ B737 and Japan Airlines’ international A350-1000, which involved the introduction of the industry’s first built-in speaker seats in partnership with Safran. Among the consultancy’s other clients are Asiana, Azul, British Airways, Cathay Pacific, Finnair, Gulf Air and Virgin Australia. A key part of Tangerine’s work with clients involves finding innovative solutions regarding sustainability, says Monica Sogn, Head of CMF (colour, material, finish).

Tangerine’s work on Japan Airlines’ A350-1000 saw the introduction of the industry’s first built-in speaker seats in partnership with Safran.

“For clients such as Japan Airlines, our sustainable CMF expertise has been helping them to meet their ESG goals by helping them to make better informed decisions about the materials they will use for their retrofit programmes,” she says. In addition to finding and advising on the right materials, Tangerine places high priority on helping its clients find the lightest weight products possible.

“Weight is the biggest driver for CO2 emissions and fuel costs for an airline, and as such it is always a focus to keep it down,” says Sogn.

“It can also be about balancing the quality of the component or material and design for repairability, to prolong the lifetime of the product. For instance, if you make something too lightweight it is often not very durable.

LOT Polish Airlines’ Boeing 787 Business Class

“Achieving that balance is something Tangerine are experts in. We come at the challenge with a customer focus but also understand the technical and maintenance processes to help our clients make informed choices that get the right levels of cost vs weight vs durability.”

Whereas weight has always been a known consideration in aircraft cabin design over the years, some factors for consideration have only come into play recently, with the introduction of sustainability initiatives leading the charge.

Circularity refers to the total environmental impact of a product, and it has become more and more of a key focus for airlines and operators seeking to find the best products for their aircraft.

“People involved in aircraft cabin interior programmes are increasingly evaluating the total environmental impact of cabin interior designs as part of a ‘circular’ consideration,” says Sogn.

“This means that modularity, repairability and durability are all being considered to close the loop and quantity the total environmental impact of one choice over another one to inform decisions made during the design process.”

Southwest Airlines’ Boeing 737 Economy Class

The approach to sourcing sustainable, circular products involves transparency with clients, says Sogn, who recommends starting with a material that’s already been recycled or has come from a renewable resource. Tangerine then works with the airline to understand what happens during service to guarantee the material is robust, before factoring in considerations of after-life use and what options are available. Attaining products using circular considerations can be particularly important for business aviation clients, in addition to adopting the uptake of SAF as it becomes more readily available. “Smarter interior designs and the use of low-carbon or more sustainable luxury materials could also help to limit the environmental impact of refits,” says Tangerine’s Head of CMF.

“As with the commercial aircraft industry, modularity could be a crucial factor, so what aspects of the interior could be modified, replaced and updated without needing a wholesale rip out to update the interior to a customer’s requirements.”